Piping stress analysis is an essential activity to ensure the reliability and safety of piping lines. This analysis, crucial for the design and maintenance of industrial plants, focuses on the study of the stresses and deformations that pipelines undergo due to multiple stresses: internal pressure, heat flows, external loads and vibrations.

Understanding and properly managing these factors is essential to prevent failures, extend the life of your pipelines, and ensure compliance with relevant safety regulations. Piping stress analysis is not only a recommended practice, but it is an indispensable control step, especially in high-risk industries, such as petrochemical, energy, and gas and fluid processing.

In this article, we will explore in details what piping stress analysis is used for, its impact on piping line maintenance and safety, and how industrial design software can facilitate and optimize this process, providing engineers with the data they need to make informed decisions.

What is stress analysis?

Pipeline stress analysis plays a crucial role in ensuring the safety and operational efficiency of the entire industrial plant.

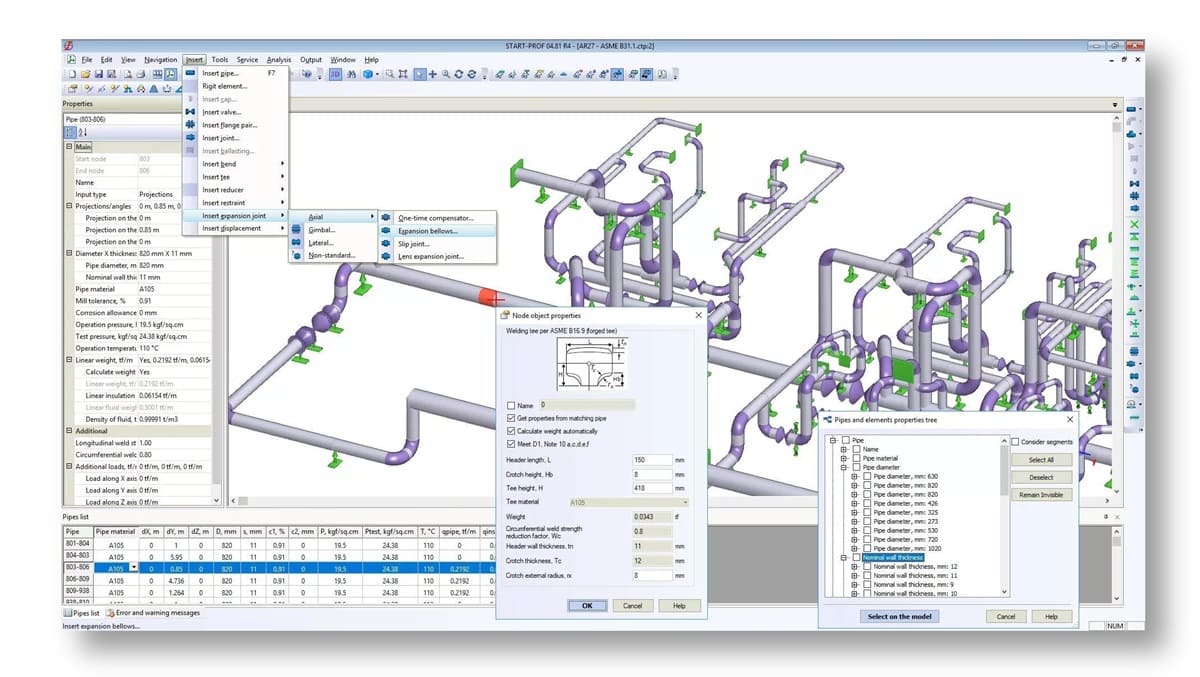

This process is essential to identify and manage the mechanical and thermal stresses to which the pipes are subjected during the normal operation of the plant. Through the use of applications dedicated to stress analysis, engineers can predict and quantify the effect of various factors, such as temperature and pressure variations, dynamic flows and external loads, including environmental ones such as wind and seismic phenomena. To carry out the stress analysis, it is possible to use new generation software, such as PASS/START-PROF, distributed by Fluids & Co, which offers a good level of functionality, combined with a user-friendly approach.

In fact, this software offers a wide range of features, including sizing calculations according to international codes and standards. With an intuitive GUI and modern user interface, engineers can start working immediately without the need for extensive training in using the software. Thanks to its built-in intelligence and ability to automatically detect any problems in the model, PASS/START-PROF simplifies the analysis process and provides efficient support to users. The analysis process allows you to assess how these forces affect the structural integrity of the pipes, highlighting potential weaknesses that could lead to failure, leaks or breaks. In addition, piping stress analysis is essential to ensure compliance with regulatory standards and technical specifications required for each type of plant, thus avoiding any penalties and interruptions in operations. In addition to these safety and compliance aspects, pipeline stress analysis plays an important role in the design and optimization of industrial plants. It provides valuable information for the choice of materials, for the sizing of pipes and for the definition of their trajectories. This process helps to effectively balance the need for a reliable and robust plant with the need to contain the costs necessary for the purchase of materials and for maintenance. For this reason, the analysis of pipe stresses is one of the main features of piping software, which provides specific commands to check that the lines are designed, installed and maintained in order to maximize operational efficiency and minimize risks.

Stressing and how to do stress analysis?

The stress analysis of pipelines should be carried out in the different phases of the life cycle of an industrial plant: from the design phase, to the installation, maintenance and subsequent modification of the system. During the design phase, it is essential to ensure that piping lines are properly sized and positioned, taking into account the expected stresses and strength limits of the materials used.

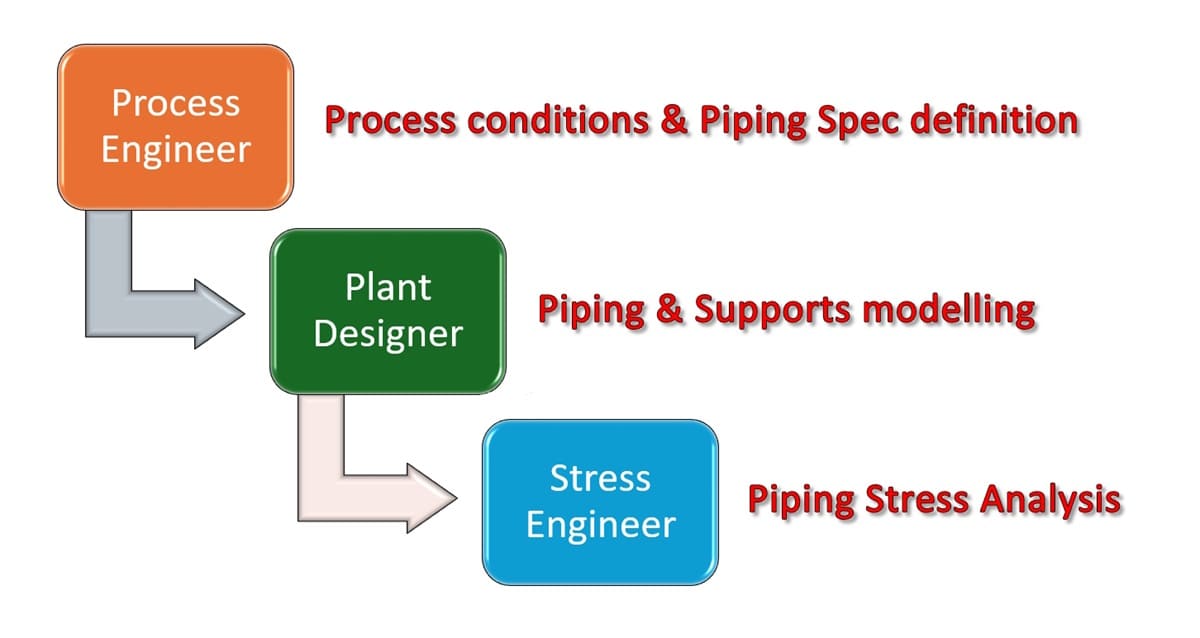

This process helps prevent future problems and optimize piping layout for efficient plant operation. It is also part of the design process of an industrial plant involving various professional figures:

- The process engineer, who must provide the specifications for the operation of the system (pressure, temperature, etc.).

- The plant layout designer, in charge of organizing the arrangement of the equipment and its interconnection in an efficient and cost-effective manner. During this phase, he is then responsible for designing the constructions of the piping supports using dedicated software: an example is ESApro Supports, the 3D design solution that allows you to extract construction drawings and bills of materials. The software also includes an extensive library of parametric elements that are generally used during the design of piping supports, such as: supports (shoes, guides, springs, etc.), attachments (collars, U-Bolts, plates, etc.), fasteners and carpentry.

- The stressist, who has the task of analyzing the various loading conditions of the pipes. This specialist must verify that the pipes are able to withstand the expected mechanical stresses, evaluating the adequacy of the routing thought in the layout phase, positioning the supports and defining their type. It also checks that the supports placed by the layout designer are of the right type and are positioned correctly. Often, subsequent routing changes are necessary to ensure that the line can sustain the expected loads without compromising safety.

Subsequently, when the plant is in operation, stress analysis becomes an integral part of maintenance operations. Periodically, or as a response to changes in operating conditions, such as changes in pressure or temperature, new analyses should be performed to assess the impact of those changes on pipeline stability. This proactive approach to maintenance prevents unexpected failures and extends the service life of piping lines.

Stress analysis is also necessary when making changes or upgrading the system. Any change in line configuration, from the use of different materials to the addition of new sections, requires careful analysis to ensure that the overall integrity of the piping system is not compromised.

To conduct effective stress analysis, engineers use specialized software that can model pipelines and simulate various operating conditions. These programs make it possible to verify from a structural point of view what has been previously designed, visualizing the effects of stresses on the pipes, identifying points of high tension, possible deformations and risks. An example is ESApro Stress Analysis Interface, which, starting from the 3D model of the plant, is able to calculate the stresses and deformations of the pipes, highlighting the points of the piping line that present criticality. This way, engineers can make informed decisions about how to design, modify, or maintain piping lines to ensure safe and efficient plant operation.

Do you want to know more? Contact us !

Francesco Pais initially wrote this post on February 9th