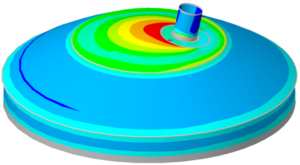

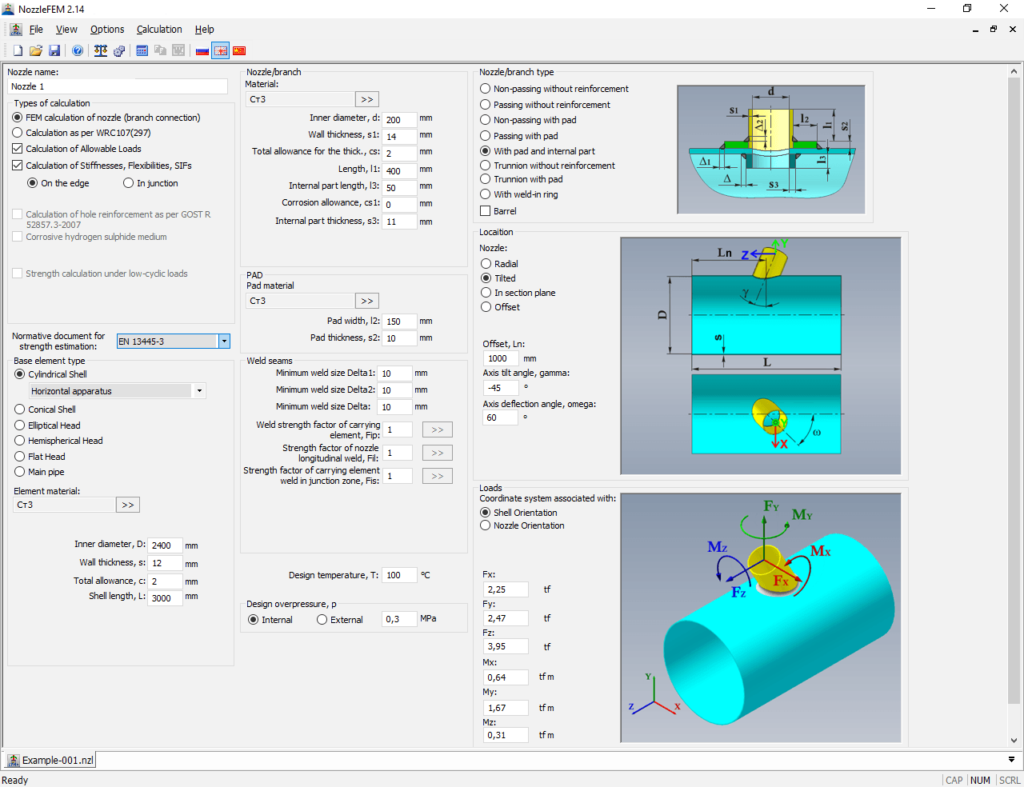

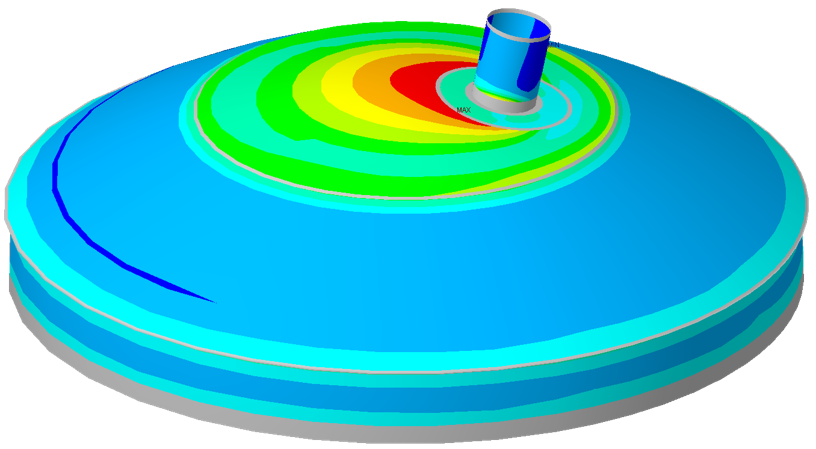

PASS/Nozzle-FEM is designed for stresses and flexibility calculation of nozzle-to-shell junctions using the Finite Element Method (FEM). The program also calculates nozzle’s allowable loads and estimates strength of the nozzle’s junctions for wide range of geometric configurations and operating conditions. Nozzle-FEM helps to provide higher level of the equipment safety along with reducing labour costs at the design stage. The program is recommended for designing and industrial safety review of oil and gas, refining, petrochemical, chemical, power and other industrial facilities.

Unlike the universal FEM programs (ANSYS, NASTRAN, COSMOS, etc.), this program does not require special training and can be used by any mechanical engineer. Creation of finite element mesh and estimation of calculation results are performed automatically. FEM calculation, as opposed to semi-analytic methods (i.e. WRC 107/297, GOST 34233.3-2007, etc.), expands the program application range and increases analysis accuracy.

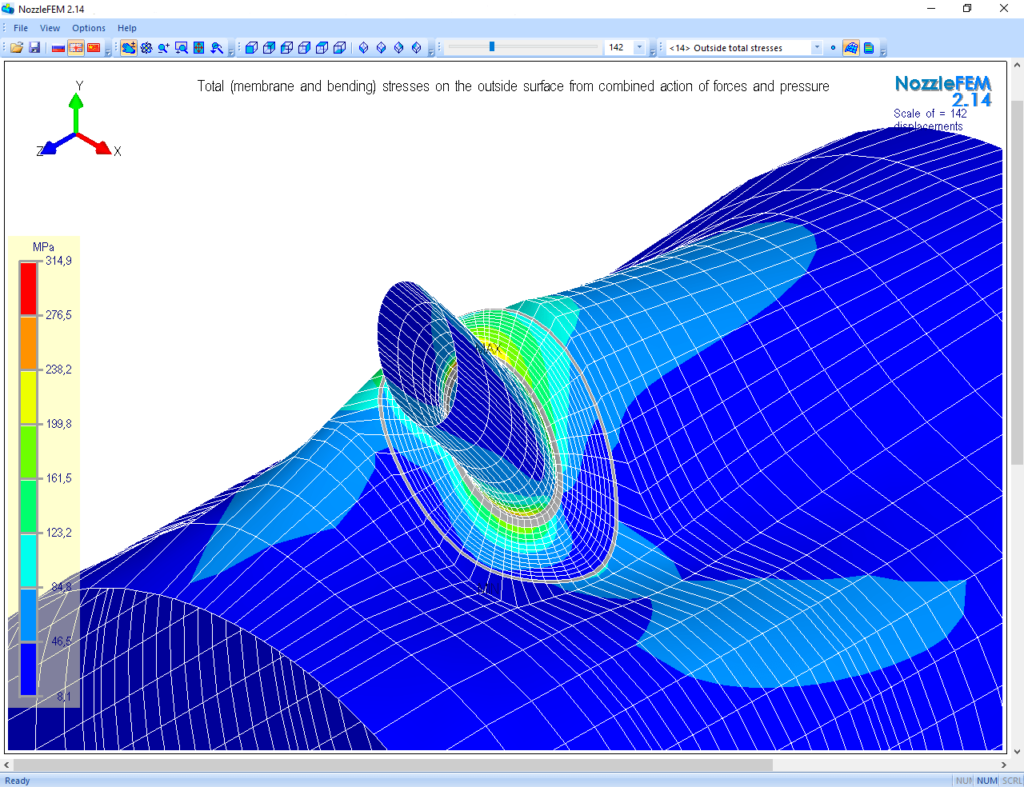

The program performs stress analysis for nozzles (including trunnions) of arbitrary geometry connected to cylindrical and conical shells, as well as elliptic, hemispherical and flat heads. Also one performs stress analysis of special cases: bend stanchion, support skirt, rectangular plate. It takes into account vessel boundary restraints and loads on the nozzle from the adjacent pipeline. Both nozzle and shell membrane, bending and total stresses can be calculated. Calculation of the pipe branch connections is also implemented, enabling detailed stress analysis of non-standard tees and pipelines branch connections.

Along with stress and stability analysis the program also performs nozzle-shell junction flexibility calculation, as this flexibility can considerably influence vessel and piping stresses. During stress analysis of pipeline systems nozzle-vessel junctions are often simulated by anchor supports which leads to overestimation of stresses and tensions. In order to automatically create the appropriate non-standard support in the calculation model, the nozzle-shell junction flexibility calculated by Nozzle-FEM can be passed into the PASS/START-PROF piping stress analysis program.

Integration

PASS/Nozzle-FEM model can be created and transferred from PASS/EQUIP software.

The special variant of PASS/Nozzle-FEM has been developed for tie-ins (tees and fittings) and shell-to-nozzle junction calculation as per WRC and GOST, to be called directly from PASS/START-PROF software. Any Nozzle-FEM results can also be user in the piping system analysis by PASS/START-PROF in manual mode.

PASS/Nozzle-FEM does not require special training and can be used by any mechanical engineer.