Trajectory design and post-drilling inflow performance analysis for a radial drilling operation with skin factor assessment.

The challenge

The radial drilling completion was designed to enhance inflow performance and reduce the high skin values previously identified in the producing interval.

- Area: Central Asia – Reservoir: Oil sandstone – Depth: MD – 19,482.61 ft, TVDSS – 18,819.52 ft – Initial Skin: +2.83 – Objective: Improve inflow performance and evaluate skin reduction through radial channel drilling

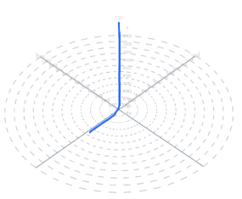

3D visualization of radial channel trajectories

The solution

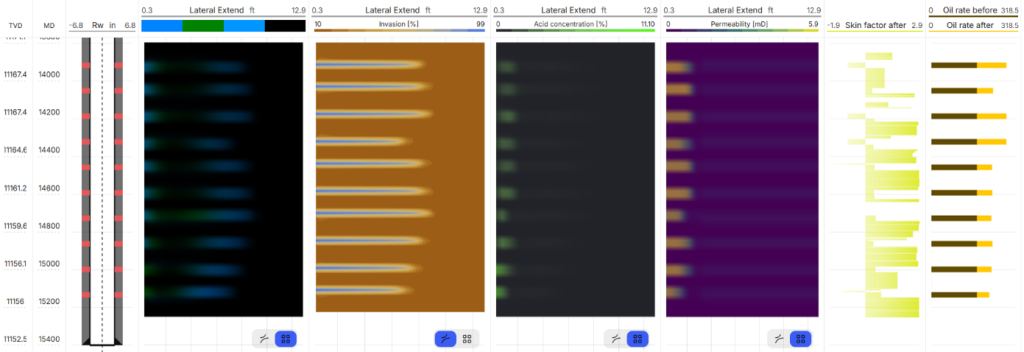

A retrospective analysis of the well’s production regime determined the initial skin factor as +2.83. Using WellStim, a model of the main wellbore and three radial channels was created to simulate the geometry and hydraulic behavior of the stimulation system.

Lithological structure and main well trajectory

Parameters of Radial Channel Trajectories

| Parameter | Channel 1 | Channel 2 | Channel 3 |

|---|---|---|---|

| Measured depth of exit point (ft) | 5741.47 | 5741.47 | 5721.78 |

| Borehole length (ft) | 45.93 | 45.93 | 45.93 |

| Exit angle from borehole (zenith, °) | 0.07 | 0.07 | 0.05 |

| Exit angle from borehole (azimuth, °) | 52.60 | 52.60 | 196.44 |

| Angle build-up (zenith, °) | 88.20 | 88.10 | 88.12 |

| Angle build-up (azimuth, °) | 0.00 | 120.00 | -120.00 |

| Channel diameter (ft) | 0.23 | 0.23 | 0.23 |

3D visualization of designed radial channels

The main wellbore trajectory and reservoir petrophysical model served as inputs for the simulation of radial trajectories and subsequent inflow performance evaluation.

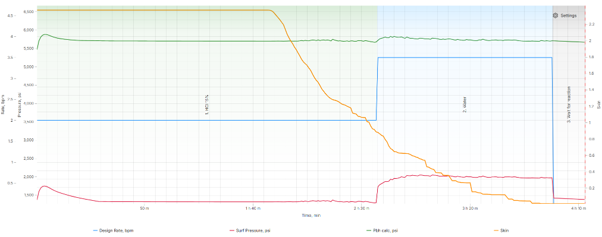

Well operating regime before radial perforation

The results

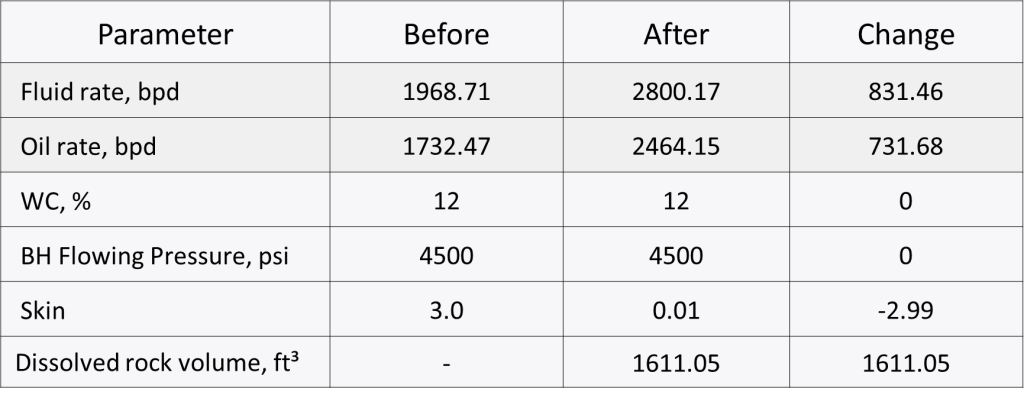

Following the drilling and completion of three radial channels, inflow performance improved substantially. The skin factor decreased from +2.83 to -3.11, confirming efficient removal of near-wellbore damage and improved reservoir connectivity.

| Parameter | Before Radial Perforation | After Radial Perforation |

|---|---|---|

| Fluid rate (bpd) | 94.35 | 214.04 |

| Oil rate (bpd) | 13.21 | 29.97 |

| Skin | +2.83 | -3.11 |

Production analysis – actual vs calculated

Key achievements:

- 127% increase in fluid production rate

- 127% increase in oil production rate

- Complete skin removal and negative skin achieved (from +2.83 to -3.11)

- Three radial channels successfully drilled and completed

- Improved reservoir connectivity and near-wellbore flow conditions

Summary

This case demonstrates WellStim’s capability to:

- Design and simulate radial drilling trajectories with precision

- Model inflow and skin performance before and after completion

- Quantitatively evaluate productivity improvements achieved by radial stimulation

The radial drilling operation led to substantial production gains while effectively creating new drainage pathways in the sandstone reservoir, confirming the effectiveness of WellStim’s radial drilling design and simulation workflow for optimizing productivity.