ESTECO Autonomous Optimization expedite decision making and design space exploration, freeing up time and human resources.

Executive Summary

Digitization is sweeping the globe, opening the doors of innovation for many organizations through the provision of tech-driven, intelligent ways of working. Within the world of simulation, automation is a leading digital technology that’s proving its worth, addressing the challenges today’s users face in the simulation space, while accelerating and democratizing every step in the design process.

Usability is a key issue for many working with automated solutions. Regardless of their level of expertise, individuals are faced with complex algorithms and must identify the right optimization strategies to get the best result, while taking into account the resources available to them. Such manual tasks are not only time-consuming but highly repetitive, where the design and engineering expertise of your specialist staff is not used to its full potential. As a result, organizations can lose their competitive edge and struggle to innovate.

This is where ESTECO’s advanced process automation and optimization driven design technology can help. It allows organizations to automate every sort of simulation process, integrate any solvers, run intelligent algorithms, and pick the right design. What’s more, this capability frees design and engineering experts, allowing these experts to focus on value-added tasks instead. It can also be used by non-expert users democratizing design space exploration and accelerating decisionmaking processes.

This whitepaper introduces the ESTECO Autonomous Optimization mode including its capabilities to expedite any organization’s decision-making and design space exploration phases. The benefits of automation are also revealed both for simulation and across the wider business, which can help organizations realize significant time and resource savings.

Where Autonomy Matters

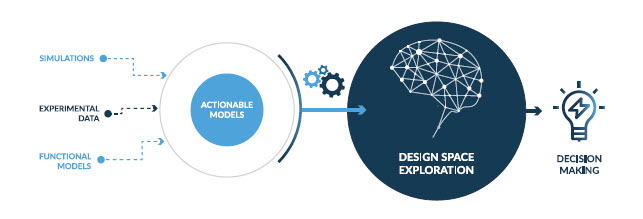

The VOLTA and modeFRONTIER solutions take existing models and transform them into actionable ones,

providing organizations with a highly efficient design space exploration.

Both use process automation and optimization driven design technologies to automate every sort of simulation process, using any solvers, to help identify the right design solution.

However, effective design space exploration is a complex issue, where users must often balance the time to

reach a solution with the quality of that solution. This is where the capabilities of Autonomous Optimization

step in, minimizing the time from the first model to the first result.

VOLTA and modeFRONTIER both provide powerful workflows to automate simulation. Using these solutions,

organizations can integrate any tool, from the simple to the very complex, and automate the entire design

process. This is what known as optimization-driven design, and it can bring the following business benefits:

- Reduced your operational costs – removing complex simulation chains from your workflow.

- Increased performance and competitive edge – evaluating thousands of designs simultaneously.

- Time savings across the design process – automatically running repetitive simulations.

As a result, our full suite of optimization algorithms can be used to pick the right design to deliver better, increasingly competitive products, in less time.

Introducing Autonomous Optimization

While VOLTA and modeFRONTIER are equipped with a range of manual optimization strategies, identifying the right strategy for your design problem can take a certain level of knowledge and expertise.

While the state-of-the-art optimization algorithms for VOLTA and modeFRONTIER are continuously improved, a more autonomous approach for non-expert users or those experts who just want to quickly test an idea was also required.

To achieve this, the Self-Initializing mode was initially introduced. Using this technique, a single parameter is set – the number of evaluations – and the algorithms then analyze the problem, automatically generating the most suitable Design of Experiments and searching for optimal solutions.The Autonomous Optimization mode takes things one step further. This is an intelligent solution, which allows users to balance the time it takes to find the optimal solution with the number of design iterations. Plus, it’s suitable for expert and non-expert users.

The algorithms featured in Autonomous Optimization mode use information gathered from the problem analysis stage to drive optimization in the right direction, only stopping when there are no further improvements available, within a reasonable period of time. Autonomous Optimization mode requires no parameters to seek optimum solutions, while minimizing the number of iterations required. Users simply press Play to start the system working.

Introducing pilOPT

pilOPT is a proprietary optimization algorithm from ESTECO, which includes multiple numerical investigation strategies. When evolving pilOPT, a definition of a multistrategy algorithm was first devised, which was capable of solving a wide range of problems. The quality of the solutions was then evaluated until satisfactory results were produced by pilOPT. Autonomous pilOPT is accessible to all users, who can configure all the necessary ingredients for an optimization run and check the inputs. When everything is ready the user just clicks Run.

pilOPT can enable collaborative decision making across an organization. It has already helped a broad range of businesses working across multiple sectors and industries turn their data into valuable insights, compare and validate design solutions and access key product performance metrics.

For example, pilOPT was recently utilized to improve the performance of a blast furnace in a plant in Trieste, Italy.

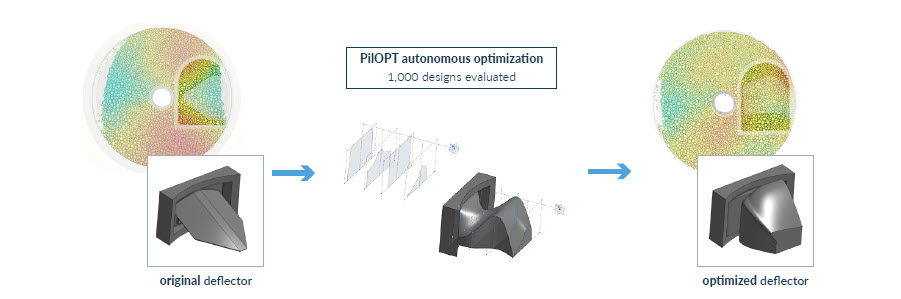

Uneven material distribution inside the furnace’s toploading hopper was reducing the efficiency of the cast iron process because the layers in the furnace were not uniform. To overcome this issue, modeFRONTIER was coupled with Rocky DEM simulation software to understand the materials’ behavior and optimize the design of the hopper’s deflector.

Following the initial design and device optimization processes, the pilOPT algorithm was then used to run

three optimization studies across the proposed designs. Thanks to the Autonomous Optimization mode,

the plant’s engineers could evaluate more than 1,000 designs in just a few weeks, without having to set any

parameters.

(courtesy of ESSS and Acciaierie Arvedi)

The entire project provided remarkable time-saving benefits, where modeFRONTIER saved 130 hours of

computational time. The human time savings were also significant. Without modeFRONTIER and the Autonomous Optimization tools, engineers would have had to manually change the geometry of the deflector for every simulation, wasting significant amounts of time.

By automating the process, design engineers could launch the optimization stage with ease and avoid the painstaking process of manually combining the output from multiple applications. This allowed the engineers to seamlessly compare and validate different design solutions, while accessing key performance metrics to help boost the performance of the plant.

Core Values and Benefits

Find better design solutions, faster

Autonomous Optimization is capable of handling hundreds of design parameters simultaneously. It can balance complex tradeoffs and quickly identify a set of optimal solutions, even for the most difficult design problems. To achieve this, Autonomous pilOPT uses a comprehensive collection of optimization algorithms, specially designed for engineering applications.

This allows users to meet contrasting design objectives and improve the product performance. As a result, the smart, self-learning algorithms from ESTECO can guide users to optimal solutions in less time and with less computational effort.

Fully exploit your expertise and resources

Automation frees design and engineering experts from repetitive tasks, while democratizing the design process, allowing non-experts to be involved in this stage. This not only brings consistency across the design process, as one person can see a design through from start to finish, but also minimizes human error.

Autonomy across every methodology

Autonomy is used across multiple areas of VOLTA and modeFRONTIER, including Design of Experiments technology and Response Surface Modeles methodology. A complete set of numerical tools are now available covering deterministic, stochastic and heuristic methods for both single and multi-objective problems, allowing users to gain valuable insights from their data, compare and validate design solutions, and access key product performance metrics.

This expedites innovation, helping organizations maintain a competitive edge by reducing design process complexity and allowing users to make better decisions with ESTECO’s advanced tools that, of course, include Autonomous Mode.

In Conclusion

With VOLTA and modeFRONTIER, organizations can discover the ultimate design process optimization and automation tools to reduce complexity, improve efficiency and cut their development times.

The Autonomous Optimization mode is a powerful tool, massively streamlining the design process and helping organizations find better design solutions, faster. Businesses can meet contrasting objectives and improve product performance with ease, while fully exploiting their design engineering expertise and resources.

To summarize, Autonomous Optimization mode both accelerates and democratizes the design process, providing organizations with a competitive advantage and futureproofed tools for an increasingly digitized world.

For more details, visit ESTECO or contact us.