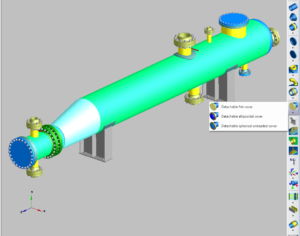

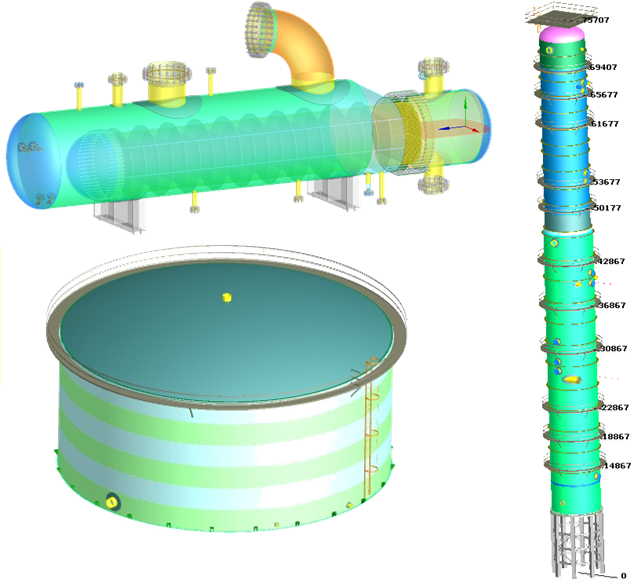

PASS/EQUIP provides pressure vessel strength and stability analysis for horizontal and vertical vessels, columns, storage tanks, as well as shell, tube, and air cooled heat exchangers under static and seismic loads in order to evaluate bearing strength in operation, test, and assembly states. Applications include designing, revamping and testing of vessels. It also makes compliance calculations for power, oil-refining, chemical, petrochemical, natural gas, petroleum, and other related industries.

PASS/EQUIP also provides finite element analysis of arbitrary vessel nozzles to estimate their stress, stiffness and allowable loads. The results can be automatically transferred to PASS/START-PROF to be used for piping stress analysis.

PASS/EQUIP combines sophisticated calculation capabilities and code compliance with ease-of-use to deliver simulation of pressure vessels for strength and stability by “regular” engineers and designers. Detailed calculation reports, produced by the program, contain comprehensive information (including all equations, intermediate results, and plot of forces and moments) and are ready to be delivered to any authorities or equipment certification body.

New employees can begin performing pressure vessel analysis in days rather than months!

Due to the large number of users and feedback from specialists in different branches of industry PASS/EQUIP continues to steadily evolve to meet modern demands. PASS/EQUIP is constantly verified and cross-test with similar programs.

Perform calculations in PASS/ EQUIP provides several benefits including: increased reliability and operational safety of equipment for various applications, improved the coordination of the project with regulatory authorities, and reduced costs and time.

PASS/EQUIP has a modern intuitive user interface, documentation and help system and our specialists provide application and technical support.

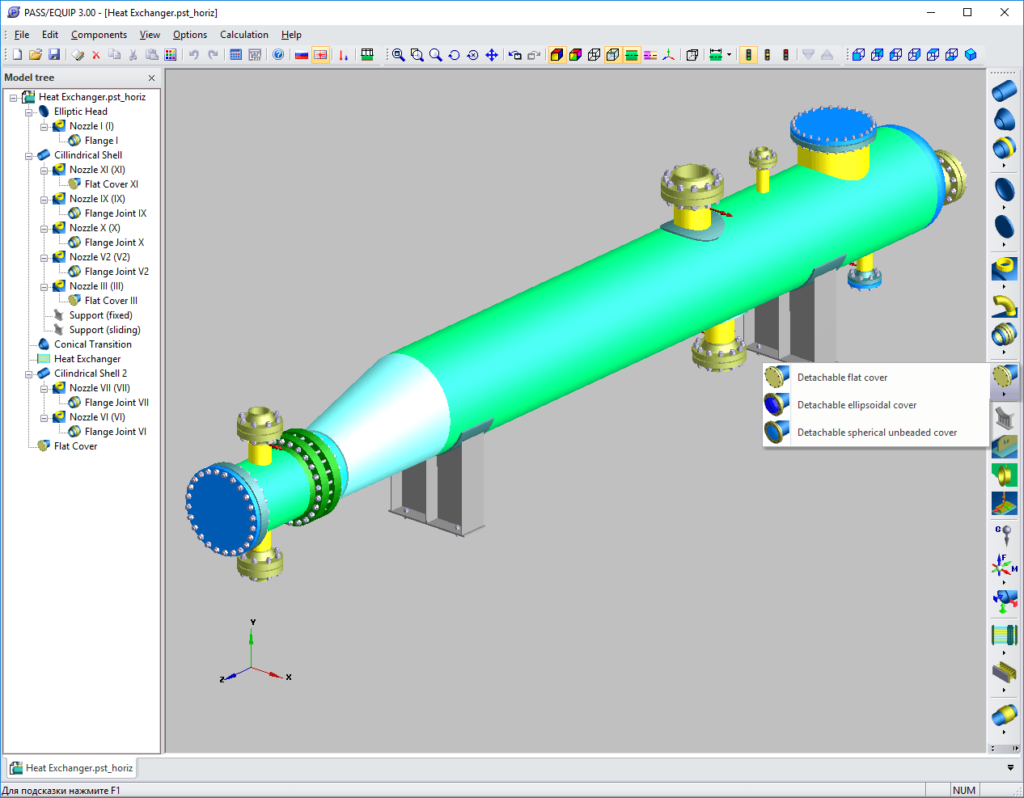

PASS/EQUIP provides the ultimate in usability by “regular” engineers allowing them to focus on equipment design. The user defines the equipment type, geometrical adjectives, material of the vessel components, type and allocation of supports, test type, and loading rates. Selection of vessel elements and materials is made from the vast databases, which can be updated by the user.

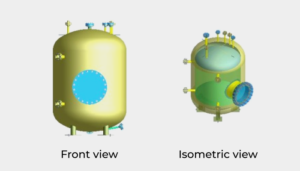

3D graphic display of equipment geometry is provided. You have the possibility of editing the color of separate elements or the whole model, with views to make it possible to see internal elements. Powerful 3D modeling opportunities also support export to various CAD formats, so the user could continue work on vessel design in his favorite CAD environment.

PASS/EQUIP does not require special training and can be used by any mechanical engineer.